Blogs

Aluminium LED PCB Board manufacturing

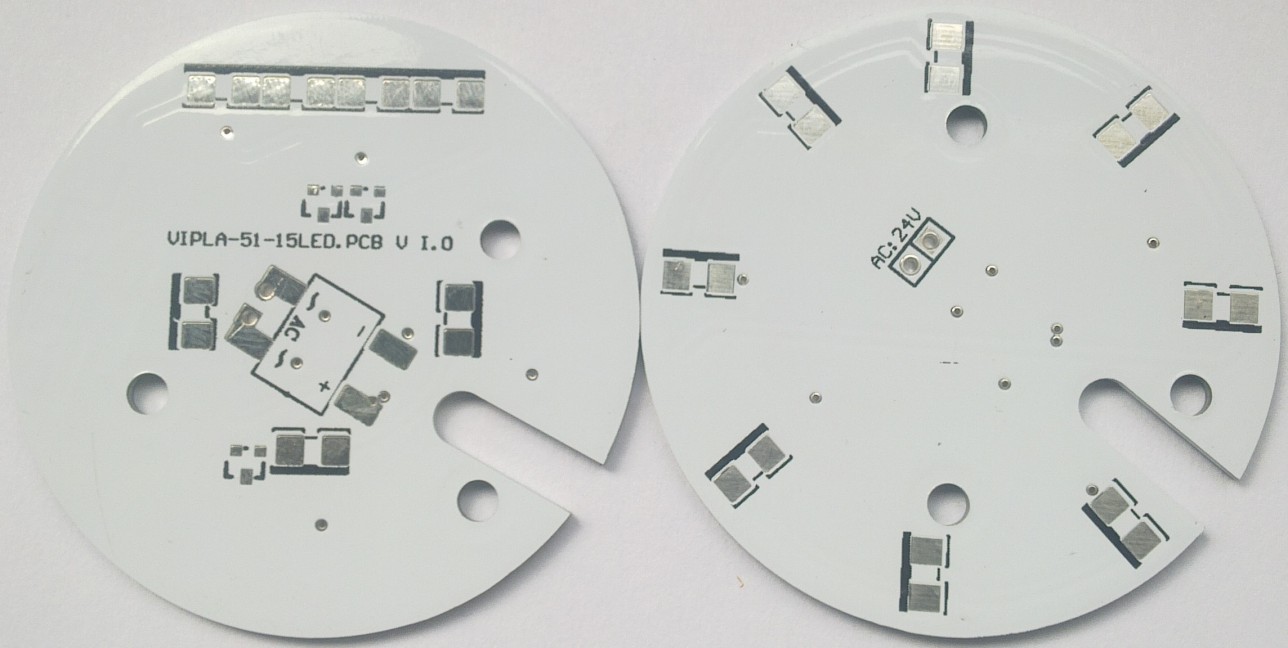

Aluminum PCB, or Aluminium PCB, also called Alu PCB, is one of Insulated Metal Substrate (IMS) PCBs, and is also one of the most commonly used Metal Core PCBs (MCPCB) nowadays. HitechPCB manufactures Aluminum printed circuit boards (PCB) with a full selection of high-performance substrates, and we work to be the best aluminum PCB manufacturer and provider no matter you need prototypes or high-volume production quantities. Aluminum PCBs typically are single-sided, but also can be double-sided as well. While, multilayer Aluminum PCBs are highly difficult to manufacture.

Thermal conductivity and thermal resistance of Aluminum LED PCB

As a widely used electronic component Aluminum LED PCB's thermal conductivity and thermal resistance are of great significance. The thermal conductivity of led Aluminum LED PCB is the quantity describing the conductor's ability to conduct heat, which can reflect the material's ability to conduct heat. Thermal resistance refers to the change rate of the temperature difference between the two surfaces during the heat conduction process of the surface of the object. In the design and application of electronic components, the thermal conductivity and thermal resistance of led Aluminum LED PCB play a decisive role.

Due to the different structure and composition of led Aluminum LED PCB, its thermal conductivity and thermal resistance will be different. Generally speaking, the greater the thermal conductivity of the led Aluminum LED PCB, the stronger the heat conductivity of the surface; And the smaller the thermal resistance, the smaller the temperature difference between the two surfaces. To sum up, the thermal conductivity and thermal resistance of led Aluminum LED PCB are very important parameters, which can affect the performance and service life of electronic components.

For different application requirements, the thermal conductivity and thermal resistance of led Aluminum LED PCB will be different. For example, in high temperature environments, Aluminum LED PCB with low thermal resistance and high thermal conductivity should be used; On the contrary, if it is in a low temperature environment, the Aluminum LED PCB with large thermal resistance and small thermal conductivity should be selected. Therefore, in the process of design and application, the thermal conductivity and thermal resistance of Aluminum LED PCB should be selected scientifically and reasonably according to the actual use environment and demand, so as to obtain better use effect. Hitech can provide a wide range of aluminum-based LED PCBS to suit customer requirements.

The relationship between insulating layer thickness and pressure resistance of Aluminum LED PCB

Aluminum LED PCB is a kind of basic material widely used in the field of electronics. The selection and thickness of insulating layer must be considered in the production process. Insulation layer is an important part of Aluminum LED PCB, its role is to prevent short circuit and leakage between different components on the circuit board, so as to ensure the normal operation of the entire circuit. The thickness of insulation layer is very important to the performance of Aluminum LED PCB and is closely related to the voltage it can withstand.

In general, the thicker the insulating layer of Aluminum LED PCB, the higher the voltage it can withstand. Because the thicker the insulation, the better you can isolate the different components on the board, reducing the possibility of short circuits and leakage. In addition, the thickness of the insulation layer can also affect the durability and stability of the Aluminum LED PCB, making it more durable and reliable.

However, too thick insulation can also bring unnecessary costs and manufacturing difficulties. Therefore, factors such as cost, reliability and performance must be considered comprehensively when selecting insulation layer thickness. Generally, the insulating layer thickness of Aluminum LED PCB should be between 5mil and 10mil, but can be adjusted for specific application requirements. For higher voltage requirements, a thicker insulation layer should be selected to ensure the stability and safety of the circuit board.

In summary, the insulating layer thickness of Aluminum LED PCB is closely related to its pressure resistance. Choosing the appropriate insulating layer thickness can improve the safety, stability and reliability of Aluminum LED PCB, so as to ensure the normal operation of the entire circuit. However, in the process of production, it is necessary to consider cost and performance factors to choose the most appropriate insulation layer thickness.

https://www.htmpcb.com/aluminium-pcb-c-1.html

https://www.hitechpcba.com/led-pcb-board-manufacturing

Posted in: Business

Topics:

aluminium pcb, led pcb, metal core pcb

Be the first person to like this.